|

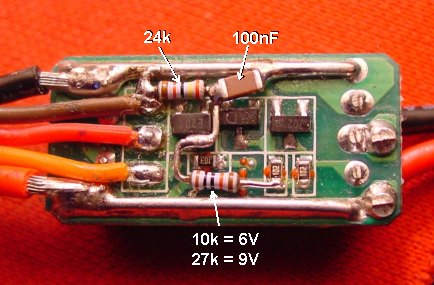

The ICS300 and ICS480 have low voltage cutoff fixed at 4.2V, which is not suitable for Lithium Polymer batteries. This modification allows these speed controllers to be safely used with a 2 cell (6V cutoff) or 3 cell (9V cutoff) Lipoly. |

|

|

The voltage detector's input pin is normally connected to +5V. This must be isolated so that a voltage divider can be connected. Resistors R1 and R2 deliver an exact fraction of the battery voltage to the detector. When battery voltage drops below the cutoff voltage, the detector sees less than 4.2V, causing it to pull its output low. This signal is monitored by the PIC12C509, which then turns off the motor to prevent the battery from becoming over-discharged. C1 attempts to smooth out any momentary battery voltage sags that may occur. |